隨著技術的高速發展,我們見證了照明設計從傳統單一光源到多樣化、高效能選擇的過程。作為在燈光行業中深耕多年的專業人士,我們深刻體會到選擇合適的照明技術對於設計師和建築師的重要性。

特別是 COB(Chip On Board)和 SMD(Surface-Mounted Device)這兩種現代照明技術,已廣泛用於製造各種應用領域的 LED 燈具和 LED 燈帶,它們為設計師們提供了更多創新且實用的解決方案。然而,我們也觀察到,要在眾多技術中找到最適合的 LED 燈具,往往讓設計師們感到選擇上的困惑。

所以,今天我們就花點時間來針對兩種 LED 芯片技術,探討它們之間的差異,並分享我們對照明的見解和應用經驗,幫助您如何挑選出最合適的燈具產品,以滿足不同空間的需求。

With the rapid development of technology, we have witnessed the transition of lighting design from traditional single light sources to diversified, high-efficiency options. As professionals with years of experience in the lighting industry, we understand the importance of selecting the right lighting technology for designers and architects.

In particular, COB (Chip On Board) and SMD (Surface-Mounted Device) are two modern lighting technologies that have been widely used in the production of LED lamps and LED strips across various applications. These technologies offer designers more innovative and practical solutions. However, we have also observed that selecting the most suitable LED lighting from numerous technologies often leaves designers feeling overwhelmed.

So today, let’s take some time to explore the differences between these two LED chip technologies and share our insights and application experiences to help you choose the most appropriate lighting products to meet the needs of different spaces.

LED Chip Technologies

LED芯片技術

LED 燈具的核心就是 LED 芯片,其工作原理是利用半導體材料發光。在 LED 芯片的封裝過程中,SMD LED 和 COB LED 採用了不同的技術路線。

The core of LED lighting is the LED chip, which operates by using semiconductor materials to emit light. In the packaging process of LED chips, SMD LED and COB LED follow different technological routes.

COB LED

LED 芯片陣列和基板的一體化封裝Integrated packaging of LED chip array and substrate.Integrated packaging of the array of LED chips and substrate.

SMD LED

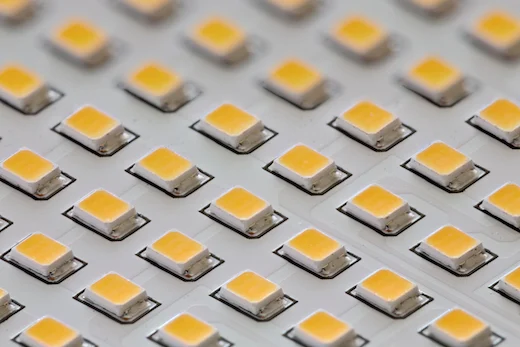

幾乎接近於扁平方形計算機芯片的設計

Design resembling a nearly flat square computer chip.

什麼是SMD?

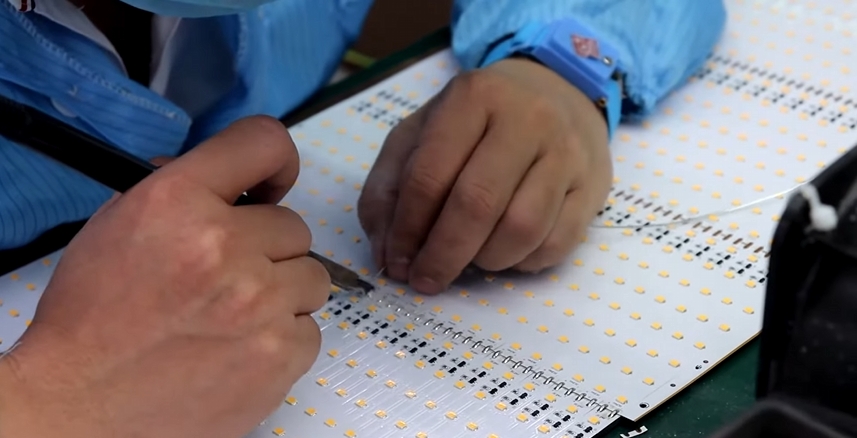

SMD LED(Surface-Mounted Device LED)是將「表面貼裝裝置」和「發光二極管」兩者結合起來的一種技術,通過使用「表面貼裝技術 (SMT)」,直接將 LED 芯片焊接在印刷電路板(PCB)一側的 LED 模組上,然後再用透明樹脂封裝。

SMD LED 的特徵是芯片呈現六面體形狀,發光面位於其中,而驅動設備的二極管則位於芯片的兩側。如果您仔細觀察 SMD LED,可以看到在其中心有一個小黑點,那就是 LED 芯片。

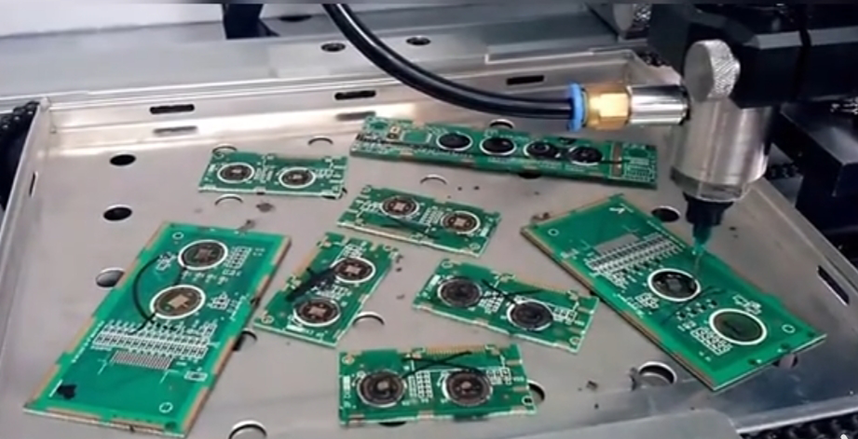

這種封裝方式的優點在於它能夠使用較少的零件來製作更緊湊的電路板,並且由於減少了電路鑽孔操作產生的廢料,使生產過程更加環保。此外,SMD 封裝技術可以配合一系列自動化機器(如拾放機)進行操作,進一步縮短了生產時間。

正因如此,SMD LED 不僅可以實現大規模量產,降低成本,還因其多功能性而廣受歡迎,成為目前應用最為廣泛的 LED 封裝技術。

What is SMD?

SMD LED is a technology that combines “surface-mounted devices” with “light-emitting diodes.” It uses Surface-Mount Technology (SMT) to directly solder the LED chip onto one side of a printed circuit board (PCB) LED module, followed by encapsulation with transparent resin.

The SMD LED is characterized by its parallelepiped-shaped chip, with the light-emitting surface located within, and the driving diode situated on the sides of the chip. If you look closely at an SMD LED, you will see a small black dot in the center, which is the LED chip.

This packaging method’s advantage lies in its ability to create more compact circuit boards with fewer components, and since it reduces the waste produced by circuit drilling operations, the production process becomes more environmentally friendly. Additionally, SMD packaging technology can be operated in conjunction with a range of automated machines (such as pick-and-place machines), further shortening production time.

As a result, SMD LED not only enables large-scale production and cost reduction but also is widely favored for its versatility, making it the most widely used LED packaging technology today.

表面貼裝技術

SMT

焊接印刷電路板

Welding PCB

LED芯片

SMD LED

SMD LED的不同變體

在探討SMD(表面貼裝技術)LED時,我們認為您還得需要了解這一類別內的多樣性。SMD LED的類型通常由一組數字標識,這些數字代表了LED芯片的尺寸和相應的亮度水平。

.SMD 3528:市場上最早推出的LED之一,其輸出功率在7到9流明之間,耗電約為0.07瓦,光效相對較低,因此多用於低亮度需求的應用。

.SMD 5050:屬於較早期高功率的晶片,其輸出功率在18到28流明之間,因此適合一般照明需求。

.SMD 5630和5730:這些LED晶片是近年開發的,以低功耗提供良好的亮度,因此在市場上非常受歡迎,特別適合用於需要高流明輸出的場所。

.SMD 2835和3014:這兩款LED因內置散熱器而被認為具有最長的壽命和最佳的性能,可有效防止光源過熱。它們通常用於照明和純裝飾用途的LED燈帶。

Variants of SMD LEDs

When discussing SMD LEDs, it is essential to understand the diversity within this category. SMD LEDs are typically identified by a set of numbers representing the size of the LED chip and the corresponding brightness level.

.SMD 3528: One of the earliest LEDs on the market, with an output power between 7 and 9 lumens, consuming approximately 0.07 watts, making it suitable for low-brightness applications.

.SMD 5050: An early high-power chip with an output power between 18 and 28 lumens, making it suitable for general lighting needs.

.SMD 5630 and 5730: These LED chips, developed in recent years, offer good brightness with low power consumption, making them popular in the market, especially for high-lumen output applications.

.SMD 2835 and 3014: These two LEDs are considered to have the longest lifespan and best performance due to their built-in heat sinks, effectively preventing the light source from overheating. They are commonly used in LED strips for both lighting and decorative purposes.

SMD LED尺寸對照明效果的影響

SMD LED的尺寸對設備的亮度和功耗有顯著影響:尺寸越大,亮度越高。

SMD LED晶片通常呈長方形,其長度和寬度隨型號而異。一般來說,無論尺寸大小,SMD LED的長度不超過5.7毫米,寬度不超過5毫米。

市場上最常見的型號包括SMD 3528、5050、5630等,這些數字實際上指的是LED芯片的尺寸(以毫米為單位)。

The Impact of SMD LED Sizes on Lighting Effects

The size of an SMD LED significantly affects the brightness and power consumption of the device: the larger the size, the higher the brightness.

SMD LED chips are usually rectangular, with varying lengths and widths depending on the model. In general, regardless of size, the length of SMD LEDs does not exceed 5.7 millimeters, and the width does not exceed 5 millimeters.

The most common models on the market include SMD 3528, 5050, and 5630, with these numbers indicating the size of the LED chip (in millimeters).

什麼是COB?

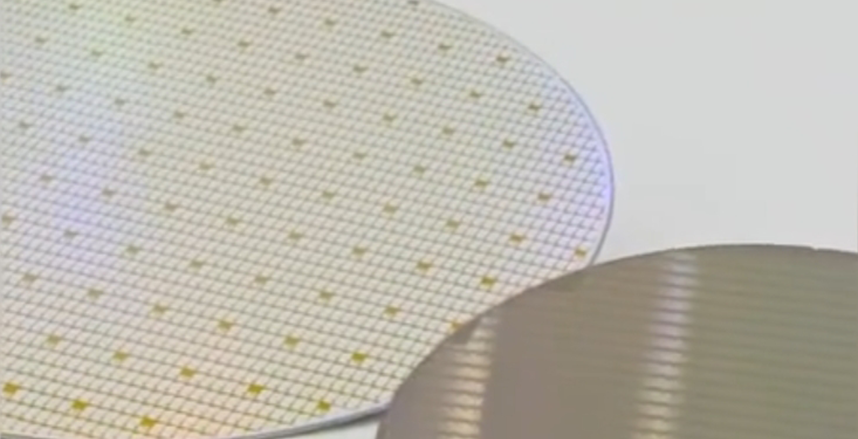

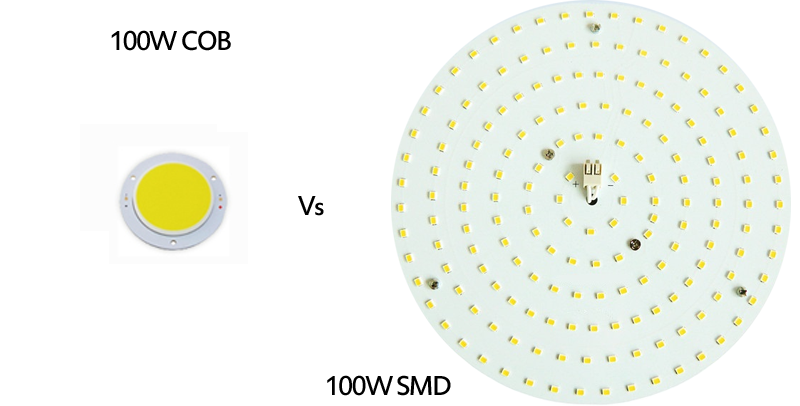

COB LED (Chip On Board LED)是一種將多顆LED芯片直接焊接在陶瓷或金屬基板上的封裝技術。這些芯片排列成一個緊湊的陣列,形成一個整體光源(即單一發光面),從而顯著提升流明密度。

由於COB LED芯片排列密集,產生的熱量也更大且集中。因此,COB LED通常使用導電膠將芯片固定在高效散熱器上,這不僅提高了熱散效率,降低了熱阻,還使LED的發光更加均勻穩定。同時,COB技術縮小了燈具的體積,實現了芯片和基板的一體化封裝,使得安裝和維護變得更加方便。

這種封裝方式省略了SMD LED中的部分封裝流程,大幅提高了光學效率,同時降低了生產成本。通過精心設計的COB LED燈具,還能有效解決市面上多顆高功率LED模組常見的「多重影」與「眩光」問題。

What is COB?

COB LED is a packaging technology that involves directly soldering multiple LED chips onto a ceramic or metal substrate. These chips are arranged in a compact array, forming a single light source (i.e., a single light-emitting surface), significantly enhancing lumen density.

Due to the dense arrangement of COB LED chips, the heat generated is also greater and more concentrated. Therefore, COB LEDs typically use conductive adhesive to fix the chips onto an efficient heat sink, which not only improves thermal efficiency and reduces thermal resistance but also ensures more uniform and stable lighting. Meanwhile, COB technology reduces the size of the fixture, achieving integrated packaging of the chip and substrate, making installation and maintenance more convenient.

This packaging method eliminates some of the packaging processes found in SMD LEDs, greatly improving optical efficiency while reducing production costs. Well-designed COB LED fixtures can also effectively address the common issues of “multiple shadows” and “glare” found in multi-chip high-power LED modules.

多顆LED芯片排列成一個緊湊的陣列

Multiple LED chips arranged in a compact array.

焊接陶瓷或金屬基板上

Soldered onto a ceramic or metal substrate.

COB LED芯片

COB LED

What Are the Differences?

兩者差異為何?

SMD LED 和 COB LED 各自具有不同的技術特點和應用優勢,這些差異使得它們在照明設計中扮演著不同的角色。

首先,SMD LED 的一大優勢在於其體積小巧(其尺寸通常只有幾毫米)且易於安裝,使其能夠輕鬆集成到各種電子設備中,如手機、電視和背光板。然而,SMD LED 的封裝方式在光品質和均勻性上有所限制, LED 芯片和基板之間存在一定的光線損耗,而且其封裝後 LED 芯片之間有間隙,可能會在近距離觀看時出現明顯的網格狀線條。

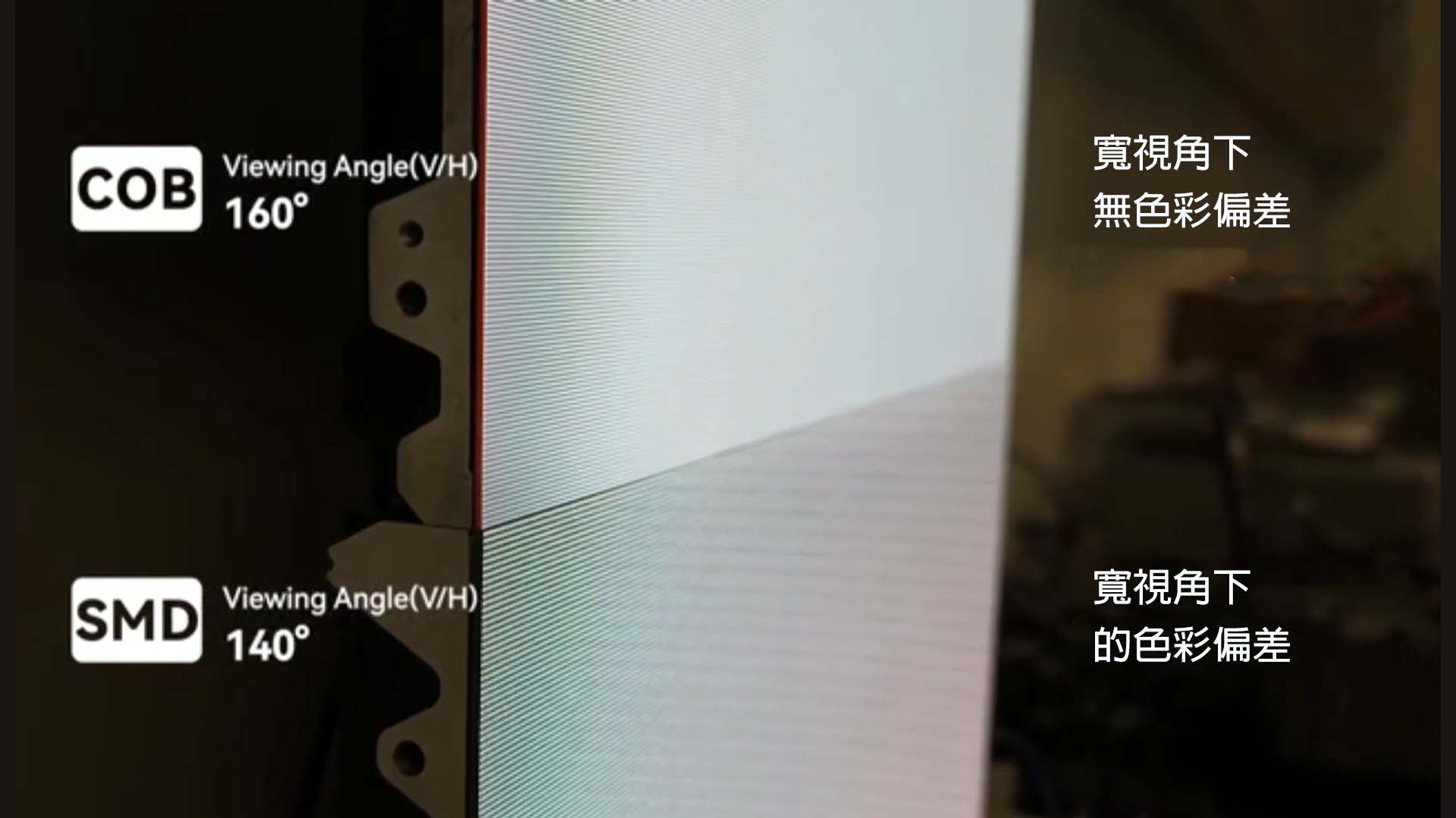

相比之下,COB LED 採用了一種將 LED 芯片直接安裝在基板上的技術,這樣不僅減少了光線損耗,還能實現更高的光效。COB LED 的芯片排列緊密,沒有間隙,因此能夠提供更加均勻的光源排布,無論是近距離觀看還是遠距離使用,都不會出現明顯的網格線或眩光問題。

但是在顏色和色溫方面,SMD LED 的適應性更強,其顏色表現非常出色。SMD 中使用了三原色(RGB),它可以更有效地使這些原色輕而易舉的實現任何色彩,並靈活地改變色溫。然而 COB LED 修改顏色和色溫的能力是有限的,但因禍得福,反而提供了更穩定的照明,不因視角而改變色彩。

SMD LED and COB LED each have distinct technological features and application advantages, which define their different roles in lighting design.

Firstly, the primary advantage of SMD LEDs is their small size (usually only a few millimeters) and ease of installation, allowing them to be easily integrated into various electronic devices, such as mobile phones, televisions, and backlight panels. However, the SMD LED packaging method has limitations in terms of light quality and uniformity. There is a certain amount of light loss between the LED chip and the substrate, and the gaps between the packaged LED chips may result in noticeable grid-like lines when viewed closely.

In contrast, COB LED uses a technique of directly installing LED chips onto the substrate, which not only reduces light loss but also achieves higher light efficiency. The closely arranged COB LED chips have no gaps, providing a more uniform light source layout without noticeable grid lines or glare, whether viewed up close or from a distance.

However, in terms of color and color temperature, SMD LED has greater adaptability, with excellent color performance. SMD uses three primary colors (RGB), making it easier to achieve any color and flexibly change the color temperature. On the other hand, COB LEDs have limited capabilities in modifying color and color temperature. Nonetheless, this limitation provides a benefit: COB LEDs offer more stable lighting that does not change color with viewing angles.

在效率方面,SMD LED 採用了先進的封裝技術,提供比傳統燈泡更高的亮度,同時具備節能環保的優勢,不僅壽命長、電壓要求低,光效更達到傳統照明的兩倍以上,功耗也降低至1/4以下。

而 COB LED 則具備優異的散熱能力,這是因為它的芯片直接連接到散熱片上,能夠迅速將熱量傳導出去,進一步保證了光源的穩定性和壽命。另外,COB LED 還有著系統光通量設計,摒棄了傳統按瓦數評估的方式,提供了更準確的 LED 發光效率評估,這使得它特別適用於高光輸出和均勻照明需求的應用場合,如大面積照明和需要高顯色性的情境。

不過要注意的是,在技術層面上,COB LED 的照射可能會產生陰影重疊,這在某些應用中可能影響光效。而 SMD LED 則具有多種特殊的工作電壓,這對於某些智能系統來說可能是一個挑戰。常規的智能系統多運行在 36V 至 48V 之間,但某些特殊規格的 SMD LED 可能需要特定的電壓範圍,這在設計規劃和後續維修時,需要特別考慮匹配相應的智能系統,可能會增加一些複雜性和不便。

In terms of efficiency, SMD LED utilizes advanced packaging technology, offering higher brightness than traditional bulbs, along with energy-saving and environmental benefits. It not only has a long lifespan and low voltage requirements but also achieves more than twice the luminous efficiency of traditional lighting while reducing power consumption to less than a quarter.

COB LED, on the other hand, has excellent heat dissipation capabilities because its chips are directly connected to the heat sink, allowing heat to be quickly dissipated, further ensuring the stability and lifespan of the light source. Additionally, COB LED has a system light flux design, discarding the traditional wattage evaluation method, providing a more accurate assessment of LED luminous efficiency, making it particularly suitable for applications requiring high light output and uniform illumination, such as large-area lighting and situations requiring high color rendering.

However, it’s important to note that on a technical level, COB LEDs may produce overlapping shadows, which can affect light quality in certain applications. On the other hand, SMD LEDs operate at various specific voltages, which can pose challenges for certain smart systems. While most conventional smart systems run on 36V to 48V, some specialized SMD LEDs may require specific voltage ranges. This necessitates careful consideration in design planning and subsequent maintenance to ensure compatibility with the appropriate smart systems, potentially adding some complexity and inconvenience.

目前,SMD LED 在需要靈活設計和多樣化顏色選擇的應用場景中表現出色,而 COB LED 則在需要高光效、高光質和均勻照明的應用中更為突出。

隨著市場對更高效、更小型 LED 技術的需求日益增加,這兩種技術也在不斷進步。例如,微型 SMD LED 的開發正在推動燈具的小型化,同時 COB LED 通過集成設計和更高效的光源,逐漸克服了傳統多顆高功率 LED 模組帶來的多重影和眩光問題。

Currently, SMD LED performs well in applications requiring flexible design and diversified color choices, while COB LED excels in applications requiring high light efficiency, high light quality, and uniform illumination.

As the market demand for more efficient and miniaturized LED technology continues to increase, both technologies are constantly evolving. For example, the development of micro SMD LEDs is driving the miniaturization of lighting fixtures, while COB LEDs are gradually overcoming the multiple shadow and glare issues of traditional multi-chip high-power LED modules through integrated design and more efficient light sources.

The Importance in Practical Applications

在實際應用中的重要性

室內照明

現代家居中普遍使用SMD LED光源,透過擴散片,提供均勻且不刺眼的光效。

Modern homes commonly use SMD LED sources with diffusers to provide uniform and glare-free lighting.

開放式辦公照明

現代辦公空間中常使用SMD LED燈具,提供充足的均勻照明,減少陰影並提高員工的工作效率。

SMD LED fixtures provide ample, even illumination, minimizing shadows and boosting productivity.

零售商店照明

商品展示架使用SMD LED燈條,突顯商品的質感和色彩,吸引顧客的視線並提升購物體驗。

SMD LED strips highlight product texture and color, attracting customer attention and enhancing the shopping experience.

高端餐飲空間

聚光燈使用COB LED,提供高亮度、穿透力強的光源,突出食物的細節和質感。

Spotlights use COB LEDs to deliver high brightness and strong penetration, accentuating the details and texture of food.

美術館照明

展示燈使用COB LED,以其精確的光型和卓越的顯色效果,完美展現藝術品的原色及細節,提升觀展體驗。

COB LEDs deliver precise beams and superior color rendering, showcasing artwork’s original colors and intricate details.

戶外建築照明

投射燈採用COB LED,光束強勁且壽命長,適合長時間的夜間照明需求,提升建築物的夜間視覺效果。

COB LED provides powerful, long-lasting beams, ideal for extended nighttime illumination.

Current Trends in the Chip Market

目前芯片市場趨勢

SMD LED 和 COB LED 是 LED 照明技術發展的兩大主流路線,各有特點,適用於不同的應用場景。當需要大面積、均勻光效或是長條型燈具時,以現今市場也只能用 SMD,但需要搭配擴散片以避免產生刺眼的點光源,這在家用照明中尤為普遍。由於 SMD LED 的功率範圍通常在 0.2W 到 3W 之間,因此它在家居環境中光線柔和、適用性強,且廣泛應用於 LED 燈管和燈條中。

另一方面,當需要長距離投射光、光型美觀且壽命長的光源時,COB LED 是更好的選擇。它在許多高端商業空間中,如大型百貨公司,因其光能量強、穿透性好、壽命長等特點而被廣泛使用。然而,由於 COB LED 的功率通常起步於 5W,因此對散熱設計要求更高,這需要各廠商合理計算燈具的散熱器面積與大小,以確保其穩定運行。

SMD LED 以其成本優勢占據了大部分的大面積照明市場,而 COB LED 則在追求高光效和更佳顯色效果的場合中展現了強大的競爭力。隨著技術的不斷進步,SMD 和 COB 之間的差異正在逐漸縮小,兩者在各自領域內都具有不可替代的地位。

選擇哪一種技術,取決於具體需求,沒有絕對的好壞之分。正因如此,這兩者能夠在市場上並行發展,持續推動 LED 照明技術的進步。

在這樣的背景下,我們的專業團隊可以幫助設計師挑選出最合適的燈具產品,以滿足不同空間的需求,提供更多創新且實用的解決方案,助力設計項目達到最佳的照明效果。

SMD LED and COB LED represent two important development paths in LED lighting technology, each with distinct advantages suited to different application scenarios. When large-area, uniform lighting or linear fixtures are required, SMD LED is the preferred choice. However, it needs to be paired with a diffuser to avoid harsh point light sources, making it particularly common in household lighting. With SMD LED’s power range typically between 0.2W and 3W, it provides soft light and strong adaptability in home environments, and is widely used in LED tubes and light strips.

On the other hand, when a light source is needed for long-distance projection with aesthetically pleasing light patterns and a long lifespan, COB LED is the better choice. It is widely used in many high-end commercial spaces, such as large department stores, due to its strong light output, good penetration, and long lifespan. However, because COB LED typically starts at 5W, it requires more advanced thermal design, necessitating manufacturers to carefully calculate the size and area of heat sinks for each fixture to ensure stable operation.

SMD LED, with its cost advantage, occupies a significant portion of the large-scale lighting market, while COB LED demonstrates strong competitiveness in scenarios demanding high light efficiency and better color rendering. As technology continues to evolve, the differences between SMD and COB are gradually narrowing, and each maintains an irreplaceable position in its respective domain.

Choosing between the two technologies depends on specific needs; there is no absolute right or wrong. It is this balance that allows both to coexist and continue driving the advancement of LED lighting technology.

In this context, our professional team can assist designers in selecting the most suitable lighting products to meet the needs of various spaces, providing more innovative and practical solutions to help design projects achieve the best lighting effects.

希望通過這篇文章,能幫助到您在面對此類情況時,更加得心應手。

I hope this article helps you navigate such situations with greater ease and confidence.

亮度怎麼決定?您是否也有這類困擾?

How Many Watts Are Bright Enough?幾…

LED燈為何成為現今的主流趨勢?

Origins of Electric Lighting電燈起源 H…